Creating a product

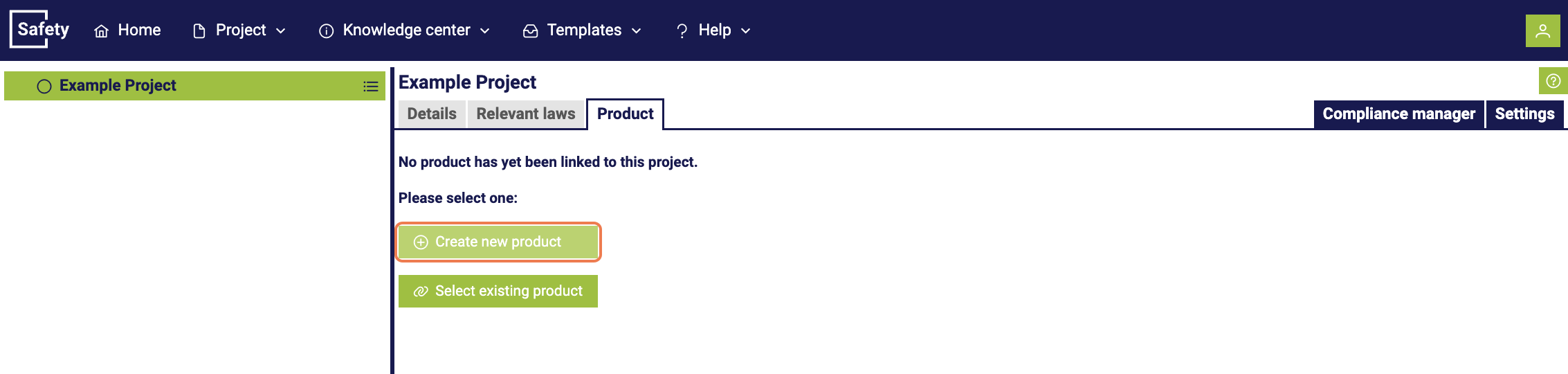

To create a product, start in the "Product" tab of a project. You can trigger the process by clicking on the plus symbol. In the following, a new product is created.

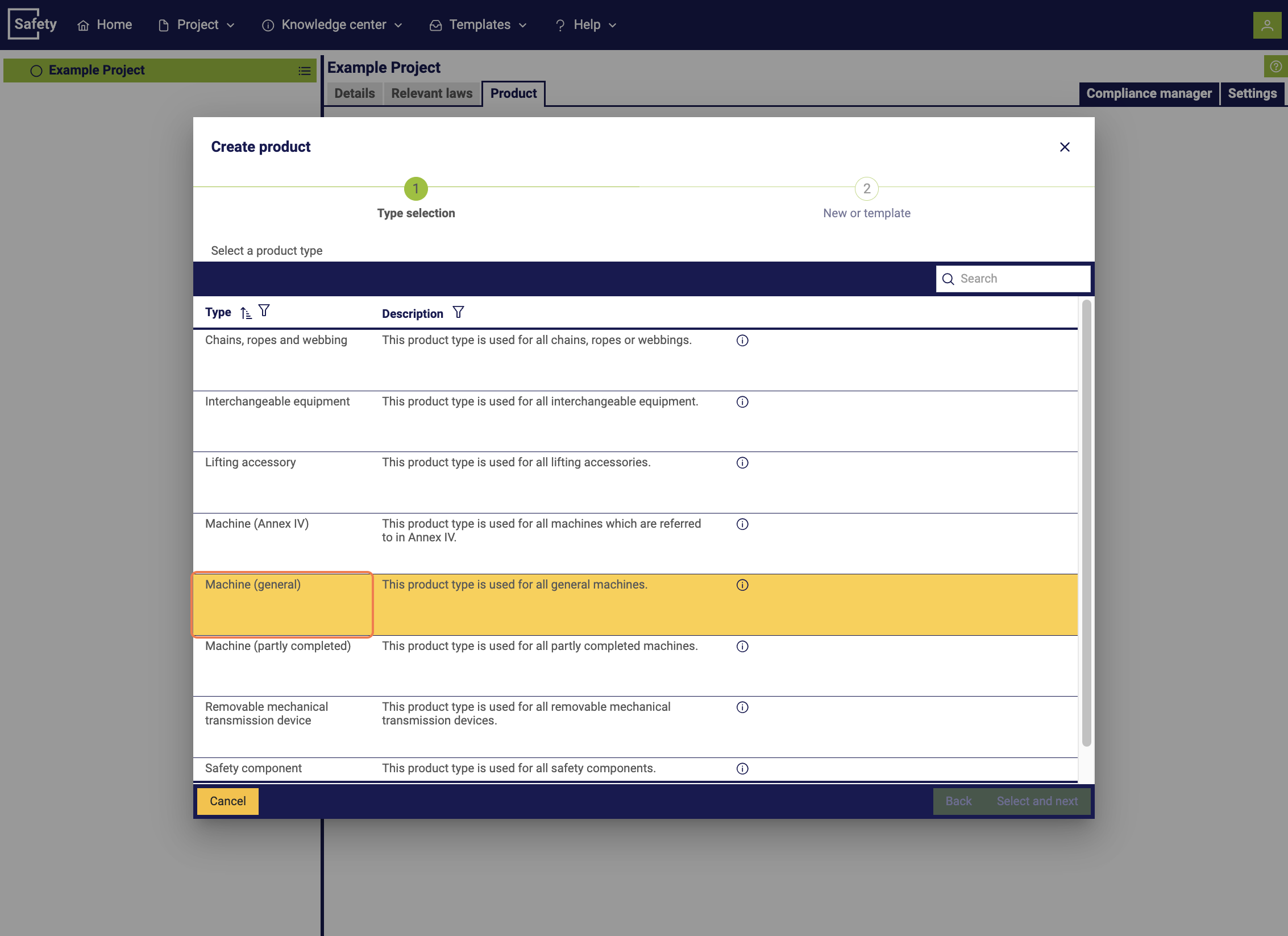

After starting the creation of a new product, a pop-up window will open. In this window, different product types with corresponding descriptions and differences in the data to be recorded are displayed. Please select the one that applies.

CE-CON Safety provides different product types to make it easier to describe products. These product types refer to the corresponding distinction types from the Machinery Directive and allow separate entries, making it easier to output the recorded data in documents without having to record all information in a continuous text.

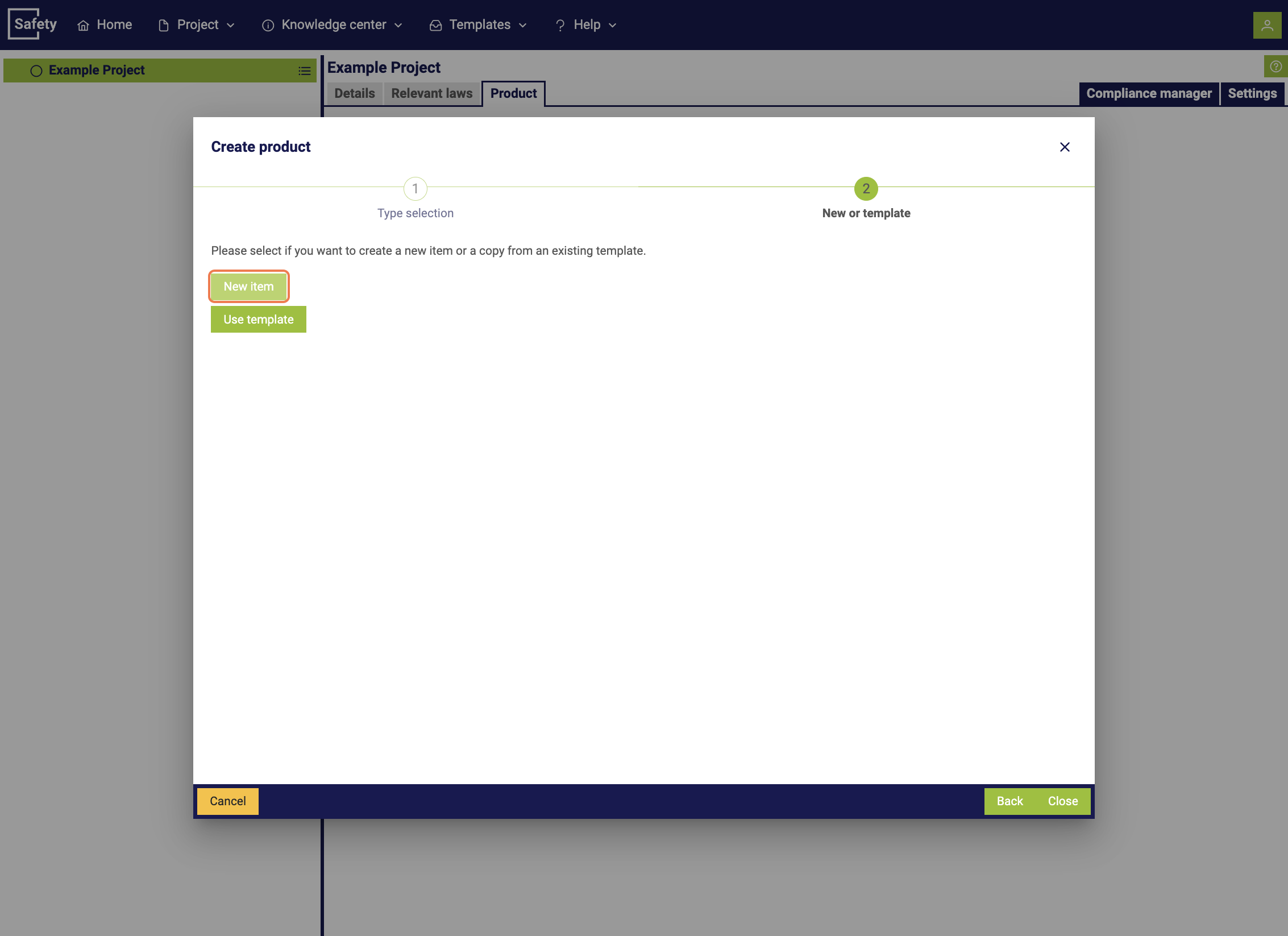

In the next step, you have the option to decide whether to create a completely new product or use an existing template. In the following, a new dataset is created.

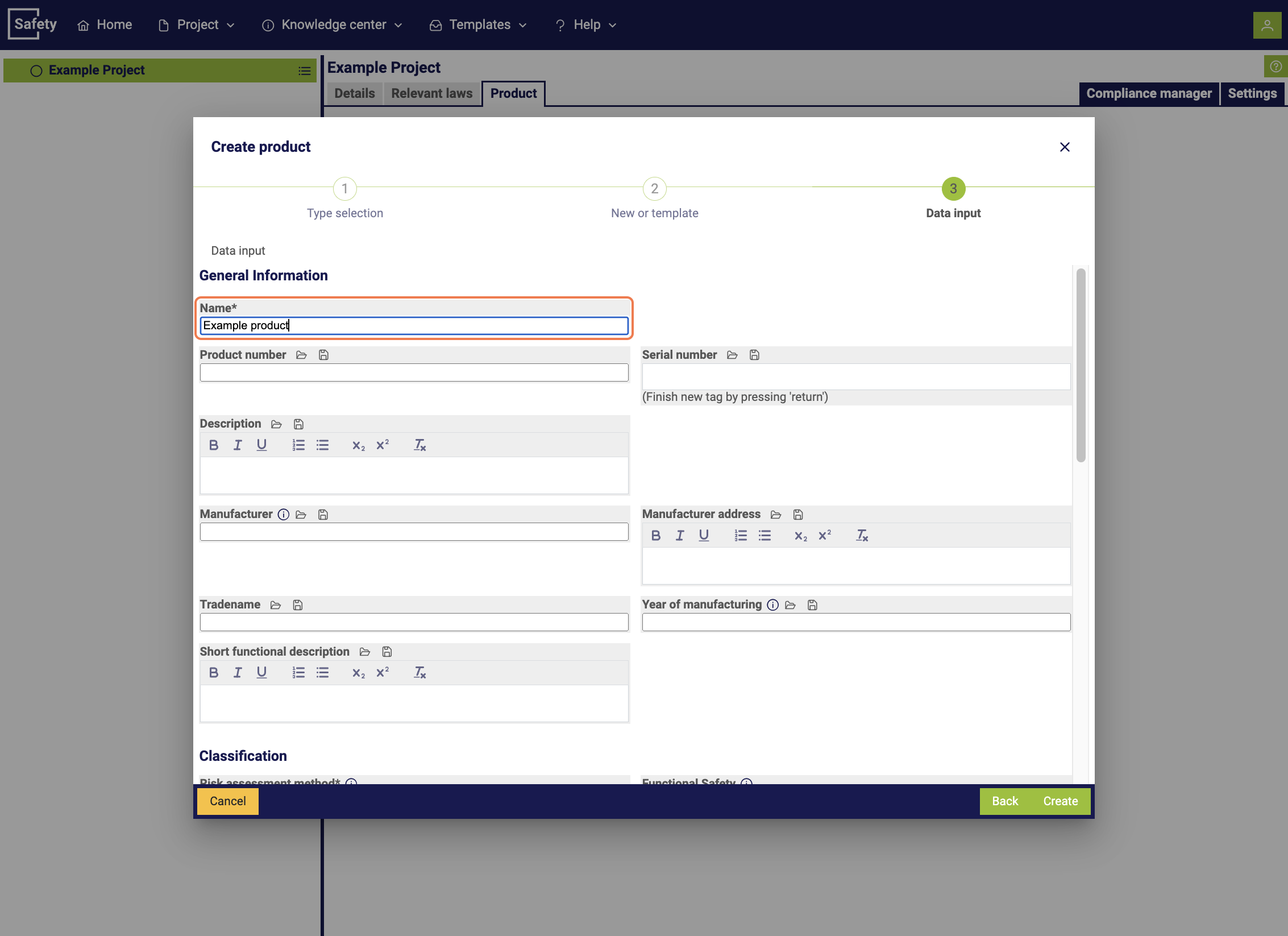

Finally, you must give the product a name and can add additional information to it.

Product limits are of great importance in defining specific restrictions for products. This information is included in documents such as the risk assessment and the declaration of conformity. There are different types of limits according to the Machinery Directive, which are differentiated as follows:

-

Intended use: This step is crucial in the risk assessment, as it defines the limits of the product, including its intended use. It is important to note that not all possible uses of a product are automatically safe. For example, machines designed for metalworking are not normally safe for woodworking and vice versa.

-

Reasonably foreseeable misuse: The manufacturer is expected to consider the reasonably foreseeable misuse of the machine. It is unrealistic to expect that all possible misuses can be considered. However, certain types of misuses can be predicted based on previous experience, accident investigations, and knowledge of human behavior.

-

Spatial limits: This includes the required movement space of the machine, the space required by people who operate the machine, and the interactions between humans and machines, such as the interface "human/machine" and "machine/energy supply".

-

Time limits: This includes the expected service life of the machine, the service life of wear parts, and the maintenance intervals.

-

Other limits: These include properties of the materials to be processed, as well as environmental conditions, such as minimum and maximum temperatures, operating conditions in enclosed spaces or outdoors, under different weather conditions, and much more.

In documents such as the risk assessment, there is a separate chapter for limits. There, the limits of the product are listed for each type of limit, to ensure clear and comprehensive documentation.